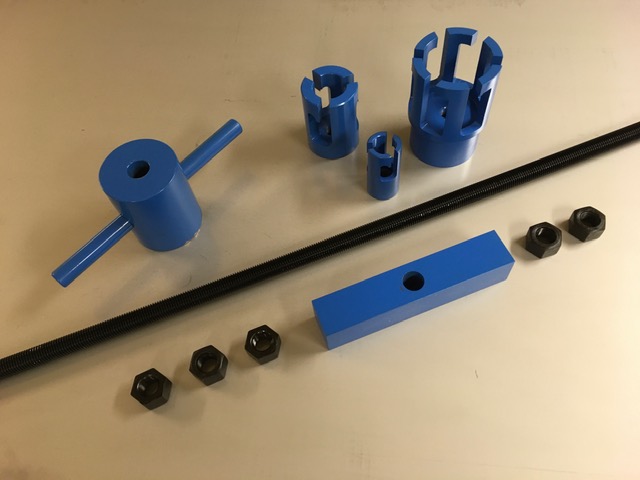

Created out of necessity, the Valve Puller is a seldom-talked-about tool that can affect the bottom line of your reciprocating plunger pump’s overall output – the quicker you can remove and replace a valve, the sooner your pump can resume its job and keep the fluid flowing. Making sure you have the correct tool to remove those valve seats is the easiest way to get them replaced.

Read More >>Delrin® and Sustakon® are both semi-crystalline thermoplastics that are used in many industries today. In the reciprocating plunger pump world, these thermoplastics are used in the disc or valve seat of the plate valve, spherical valve, or Durabla® valve and can play a key role in the reliability, durability and longevity of these valves. Since the valves are exposed to a variety of often harsh environments, it’s important to understand which thermoplastic is better suited for each application. Let’s take a closer look at them individually, and then we’ll do the apple to apple test.

Read More >>When selecting a reciprocating pump valve, it’s important to understand many critical details about the pumping application, including the pressure rating and temperature, viscosity, and composition of the fluid being pumped. Is the fluid corrosive? Will it contain abrasive solids? If so, how large might the particulates be? For example, in some mining applications, it makes more sense to select a pump valve that is engineered to withstand small solids and other abrasive materials.

Read More >>We are at it again! Triangle Pump Components, Inc. (TPCI) has trademarked more products to distinguish us from the rest of the pack. With so many products on the market today, trademarked names can help identify the efficient, quality products from the generic ones. So without further delay, here are our newly trademarked products . . .

UPDATE: Triangle Pump Components, Inc. (TPCI) is proud to announce that the CavPack® Valve Set, Resista® AR Valve, and the DynaRod® Extension Rods have been granted "Registered" trademark status!

Below is a review of the meanings behind the newly registered product names.

Triangle Pump Components, Inc. (TPCI) recently trademarked three product names for our reciprocating pump valves and components. These valves and extension rods, all of which meet ASTM and ISO 9001-2015 standards, feature names derived from various origins with significant meanings related to their features and applications.

Below is a closer look at the meanings behind three of our newly trademarked products.

Frequently occurring in pumping applications, cavitation creates bubbles or vapor cavities in a liquid as a result of rapid changes in pressure. These liquid-free voids typically form in low-pressure zones and can burst when subjected to high pressures, sending powerful shockwaves throughout the entire application.

Read More >>Over the years, the team at TPCI has noticed a recurring issue: Many companies with pumping applications will not replace their pump components when necessary. Instead of following the recommended maintenance cycles, they often wait until there’s an emergency or something breaks or fails.

Read More >>Steam is one of the chief sources of energy in the rigorous chemical processing industry. Able to create heat, change chamber pressure, separate components, provide water, trigger chemical reactions, and transfer energy in order to power various systems, steam is used in many industrial and chemical applications.

Read More >>Thanks to the leadership of Cleburne Shop Manager Jon Edson, Triangle Pump Components, Inc. has been able to

make great strides in warehouse productivity and performance.

Mr. Edson has invested his time not only in his employees, but also in the advancement of our warehouse management solutions.

His diligent work has helped to greatly improve the shipping and receiving, inventory, and manufacturing departments at TPCI.

Read More >>