During these unprecedented times, reciprocating plunger pumps around the world are experiencing a shift in productivity. While some industries like the oil & gas industry are experiencing a downturn, others like the soap, pulp & paper, and food processing industries are being pushed to produce more than ever before.

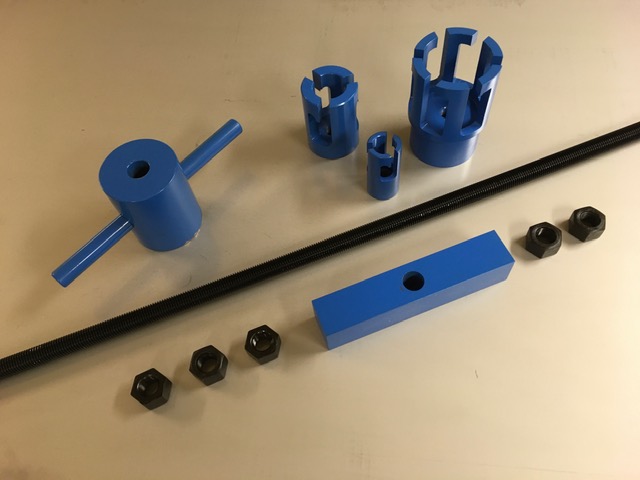

Created out of necessity, the Valve Puller is a seldom-talked-about tool that can affect the bottom line of your reciprocating plunger pump’s overall output – the quicker you can remove and replace a valve, the sooner your pump can resume its job and keep the fluid flowing. Making sure you have the correct tool to remove those valve seats is the easiest way to get them replaced.

Read More >>Delrin® and Sustakon® are both semi-crystalline thermoplastics that are used in many industries today. In the reciprocating plunger pump world, these thermoplastics are used in the disc or valve seat of the plate valve, spherical valve, or Durabla® valve and can play a key role in the reliability, durability and longevity of these valves. Since the valves are exposed to a variety of often harsh environments, it’s important to understand which thermoplastic is better suited for each application. Let’s take a closer look at them individually, and then we’ll do the apple to apple test.

Read More >>We are at it again! Triangle Pump Components, Inc. (TPCI) has trademarked more products to distinguish us from the rest of the pack. With so many products on the market today, trademarked names can help identify the efficient, quality products from the generic ones. So without further delay, here are our newly trademarked products . . .

In a perfect reciprocating pump system, suction and discharge valves should gently open and close as the plunger reaches its full stroke extension into the fluid end or full point of retreat back toward the power end. However, we all know we don’t live in a perfect world and this perfect functionality is never the reality. There is always some lag time in the opening with any model pump valve. The problem is - the more lag, the greater the problem for the pump.

Read More >>UPDATE: Triangle Pump Components, Inc. (TPCI) is proud to announce that the CavPack® Valve Set, Resista® AR Valve, and the DynaRod® Extension Rods have been granted "Registered" trademark status!

Below is a review of the meanings behind the newly registered product names.

Industrial applications that require high-pressure system components often rely on plunger pumps for successful operation. These pumps see frequent use in process technology and cleaning applications.

Read More >>In our industry there has been a shift from the somewhat standard pumping system requirements of the 60’s and 70’s to specifications that are more demanding and application specific. Today’s pumping system professionals are forced to find innovative means of increasing system output, albeit marginally, to meet the ever increasing demands of their markets. As performance expectations rise, so does the demand for valves that leverage price with increased performance. There hasn’t been a realistic and cost efficient solution to this problem until now.

Read More >>This year TPCI celebrates 100 years providing quality products, reliable support, & expert solutions.

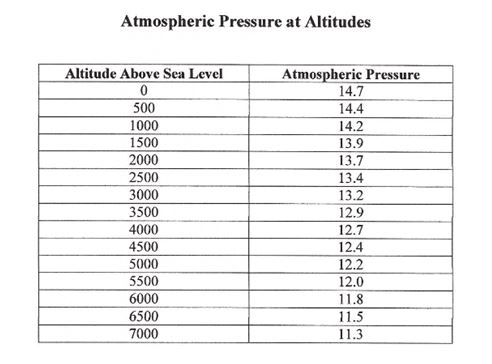

Read More >>Pump cavitation is a phenomenon that can wreak havoc on even the most durable and robust pumping systems. Blame is often unfairly cast on the construction of the pump itself. However, most times, cavitation is the result of poor system design, lack of maintenance, and improper understanding of the environmental factors that contribute to pump performance, such as sea level and vapor pressure.

The key to preventing pump damage lies in a sound understanding of a parameter called the net positive suction head (NPSH). To avoid cavitation, the pressure at all points of the fluid must remain above the vapor pressure; in other words, the available net positive suction head (NPSHa) must be sufficiently larger than net positive suction required (NPSHr) at the pump inlet.

The NPSHa is determined by the following formula:

NPSHa = Pa +/- Pg +/- Pz – Pvp – Pf – Pac

Where:

Pa = Atmospheric pressure

Pg = Gauge pressure at the supply tank

Pz = Head or lift pressure

Pvp = Vapor pressure of the liquid at its actual temperature

Pf = Pressure required to overcome friction

Pac = Acceleration pressure

Here, we will look at the various factors that affect the NPSHa value and how they influence cavitation.

Read More >>